SERVICES

PRECISION LASER CUTTING

Laser Cutting

Transforming raw metal into precision components through cutting, forming, welding, and finishing using skilled craftsmanship and advanced manufacturing processes.

Punching

Metal punching is a fabrication process where a press drives shaped tools through sheet metal to cut holes or forms quickly and accurately, producing consistent parts for further assembly or finishing.

Saw Cutting

Precision saw cutting uses automated band and circular saws to cut metal stock to length with tight tolerances, clean edges, and minimal waste, supporting downstream fabrication and assembly.

Laser Etching

Laser etching uses a focused laser to permanently mark metal surfaces with text, logos, or patterns by altering the surface layer without cutting, ensuring high precision, durability, and repeatable results.

METAL FORMING

Tube Bending

Tube bending is a metal fabrication process that shapes metal tubing into precise angles and curves using specialized machinery, while maintaining strength, accuracy, and consistent cross-section.

More

View more metal forming services that we offer.

Dimple Forming

Dimple forming is a precision metalworking process where sheet metal is pressed with matched dies to create recessed dimples, strengthening joints and allowing flush fastening for improved fit, strength, and aerodynamics.

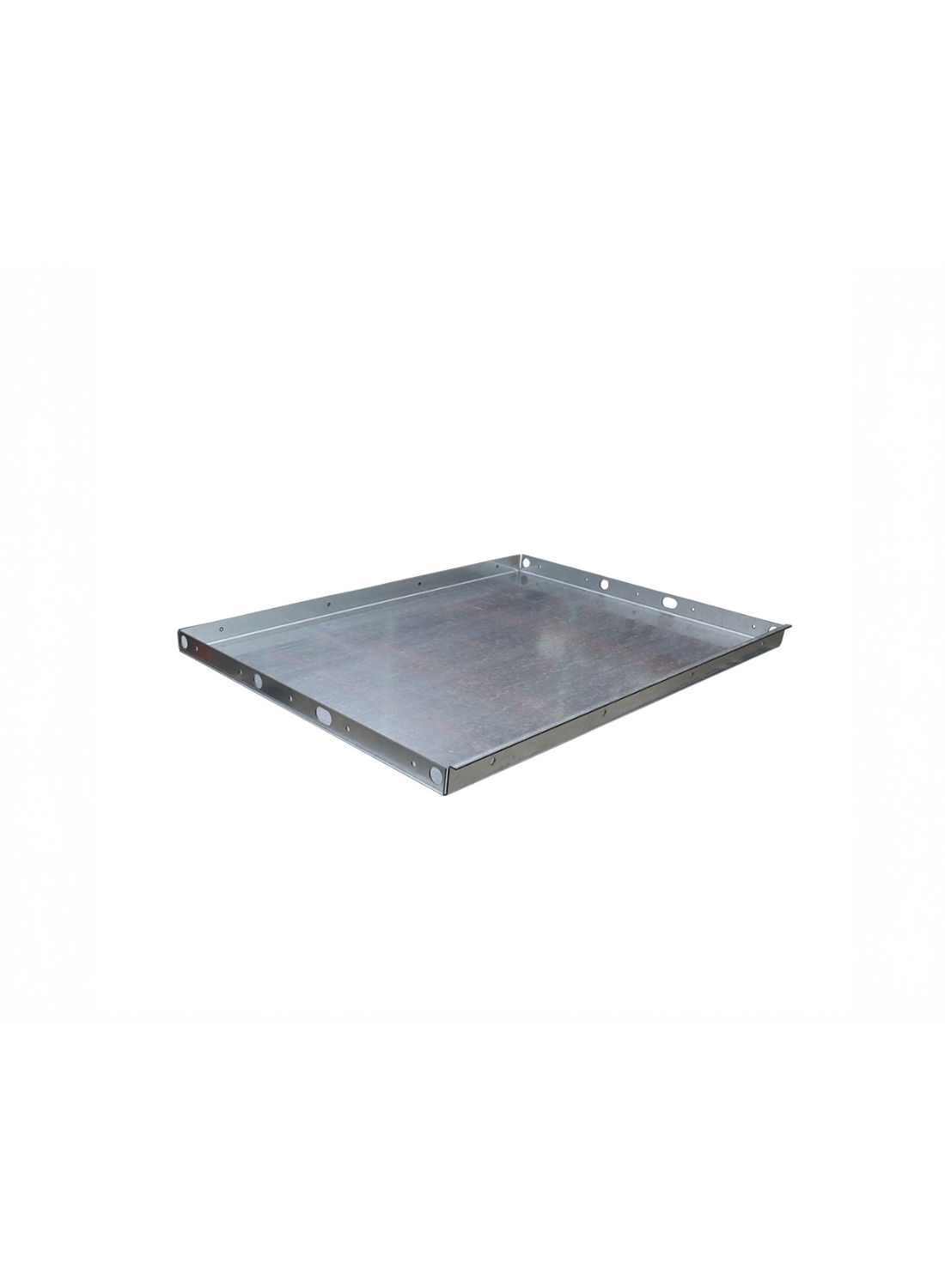

Forming / Bending

Metal forming shapes flat or solid metal into precise components using presses, rolls, and dies, applying controlled force to bend, stretch, or compress material without removing it.

WELDING

Grinding

Grinding is a finishing process where abrasive wheels remove excess material, smooth surfaces, and refine dimensions on metal parts to achieve precise tolerances, improved surface quality, and proper fit or function.

More

View more welding services that we offer.

Fastener Spot Welding

Fastener spot welding joins threaded fasteners to metal by using precise electrical resistance and pressure to create a strong, localized weld, enabling reliable attachment without drilling or compromising base material strength.

Welding

The welding process at a metal fabrication facility involves permanently joining metal components using heat, pressure, or filler material to create strong, precise assemblies that meet structural, safety, and quality specifications.

FINISHING

Powder Coating

Powder coating is a durable finishing process where dry, electrostatically charged powder is applied to metal parts and cured in an oven, creating a tough, uniform, corrosion-resistant finish without solvents.

Blasting

Abrasive blasting cleans and prepares metal surfaces by propelling grit at high speed to remove rust, scale, paint, and contaminants, creating a uniform surface profile for coating, welding, or finishing.

Tumbling

Metal tumbling smooths and finishes fabricated parts by rotating them with abrasive media, removing burrs, sharp edges, and surface imperfections to improve consistency, safety, and appearance.

Plating

The plating process applies a thin metal coating to fabricated parts using electrochemical methods to improve corrosion resistance, durability, conductivity, and surface appearance.

MACHINING

Drilling / Threading

Manual drilling and threading produce precise holes and internal threads in metal components using drill presses, taps, and hand tools, ensuring proper alignment, fit, and secure fastening during fabrication.

Fastener Insertion

“Fastener insertion is the controlled process of installing studs, nuts, or standoffs into metal parts using pressure or heat to create a permanent, high-strength attachment that ensures proper alignment and structural integrity.

Shearing

Metal shearing is a cutting process where flat metal sheets are precisely cut to size using a shear machine, applying straight-line force to produce clean, accurate edges without generating heat or chips.

Counter Sinking

Countersinking is a precision machining process that creates a conical recess in a pre-drilled hole so flat-head fasteners sit flush with or below the metal surface, improving fit, strength, and finished appearance.

MORE SERVICES

Packaging

Packaging at a metal fabrication facility involves inspecting finished parts, protecting surfaces with appropriate materials, bundling or crating components, labeling, and preparing shipments to prevent damage during handling and transport.

Shipping

Shipping at a metal fabrication facility involves packaging finished parts, verifying quantities and quality, preparing documentation, loading trucks safely, and coordinating carriers to ensure on-time, damage-free delivery to customers.

Quality Inspection

A systematic process of verifying raw materials, in-process work, and finished metal components to ensure dimensional accuracy, structural integrity, and compliance with specifications, standards, and customer requirements.

CAD Design

CAD engineers translate customer requirements into precise 2D and 3D models, optimizing parts for manufacturability, accuracy, and efficiency before cutting, forming, and welding in the metal fabrication process.