PRECISION LASER CUTTING

Precision Laser Cutting

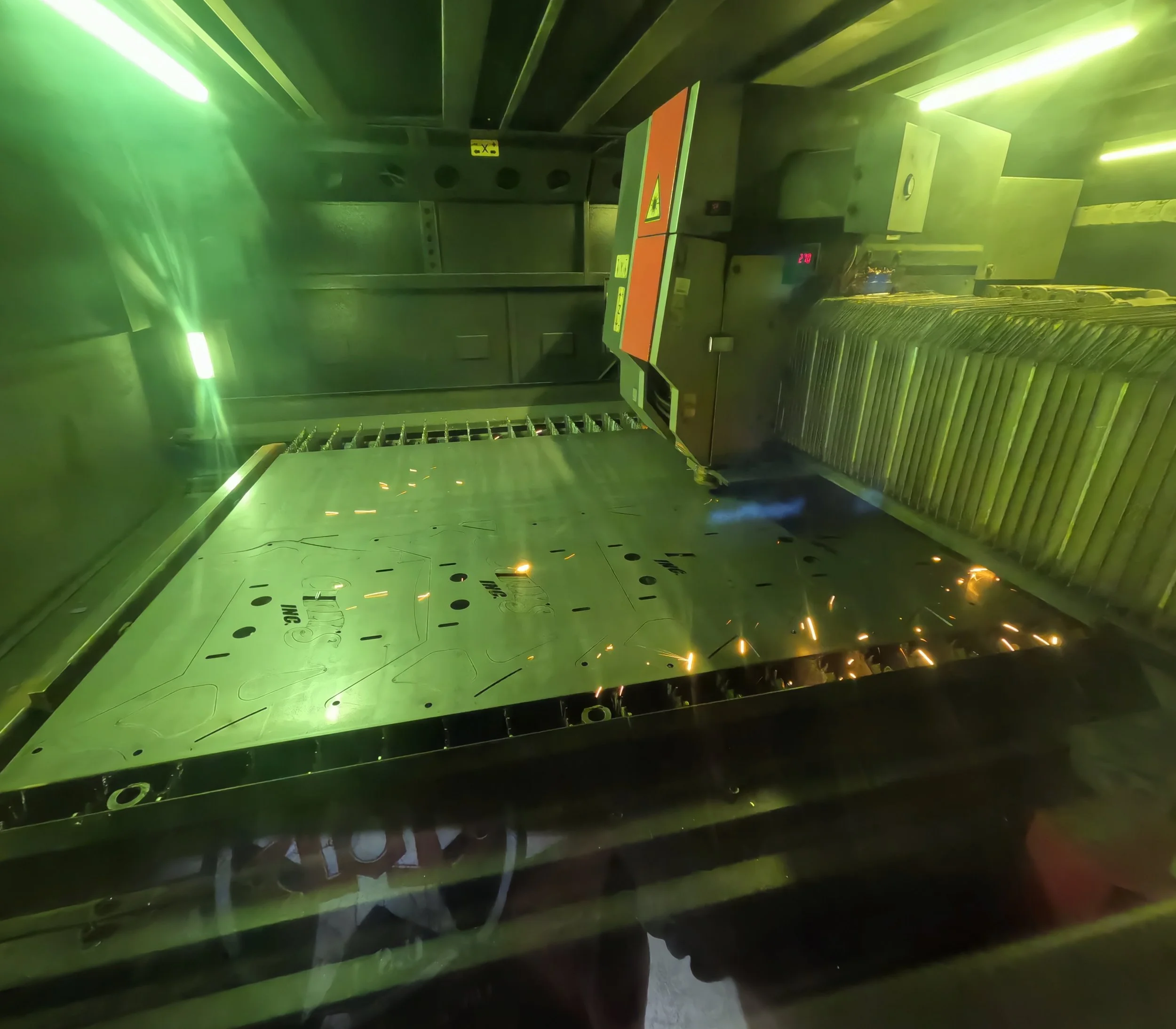

Precision laser cutting is an advanced metal fabrication process that uses a focused, high-energy laser beam to cut sheet and plate material with exceptional accuracy, speed, and repeatability. This process is ideal for producing complex geometries, fine features, and tight tolerances while maintaining a high-quality edge finish.

How It Works

Laser cutting begins with a digital part design created from CAD data. The laser system follows programmed cutting paths, directing concentrated energy onto the material surface. The laser melts or vaporizes the metal, while an assist gas—such as nitrogen or oxygen—removes molten material from the cut zone. This controlled process allows intricate shapes, small holes, and detailed contours to be produced with consistent precision across a wide range of part sizes and thicknesses.

Quality & Accuracy

Precision laser cutting delivers outstanding dimensional accuracy and repeatability. The non-contact nature of the process minimizes material distortion and eliminates tool wear, ensuring consistent results from part to part. Clean, smooth edges reduce the need for secondary finishing, and tight tolerances are maintained throughout production runs. Advanced process control allows for the reliable cutting of both thin and thick materials while preserving material integrity.

Benefits

Laser cutting offers significant advantages in efficiency, flexibility, and part quality. It enables rapid turnaround times, reduced material waste, and the ability to quickly adapt to design changes. The process supports both prototype and high-volume production and is suitable for steel, stainless steel, aluminum, and other alloys. Precision laser cutting provides a versatile, cost-effective solution for manufacturing high-quality components that meet demanding performance and appearance requirements.