LASER ETCHING

Laser Etching

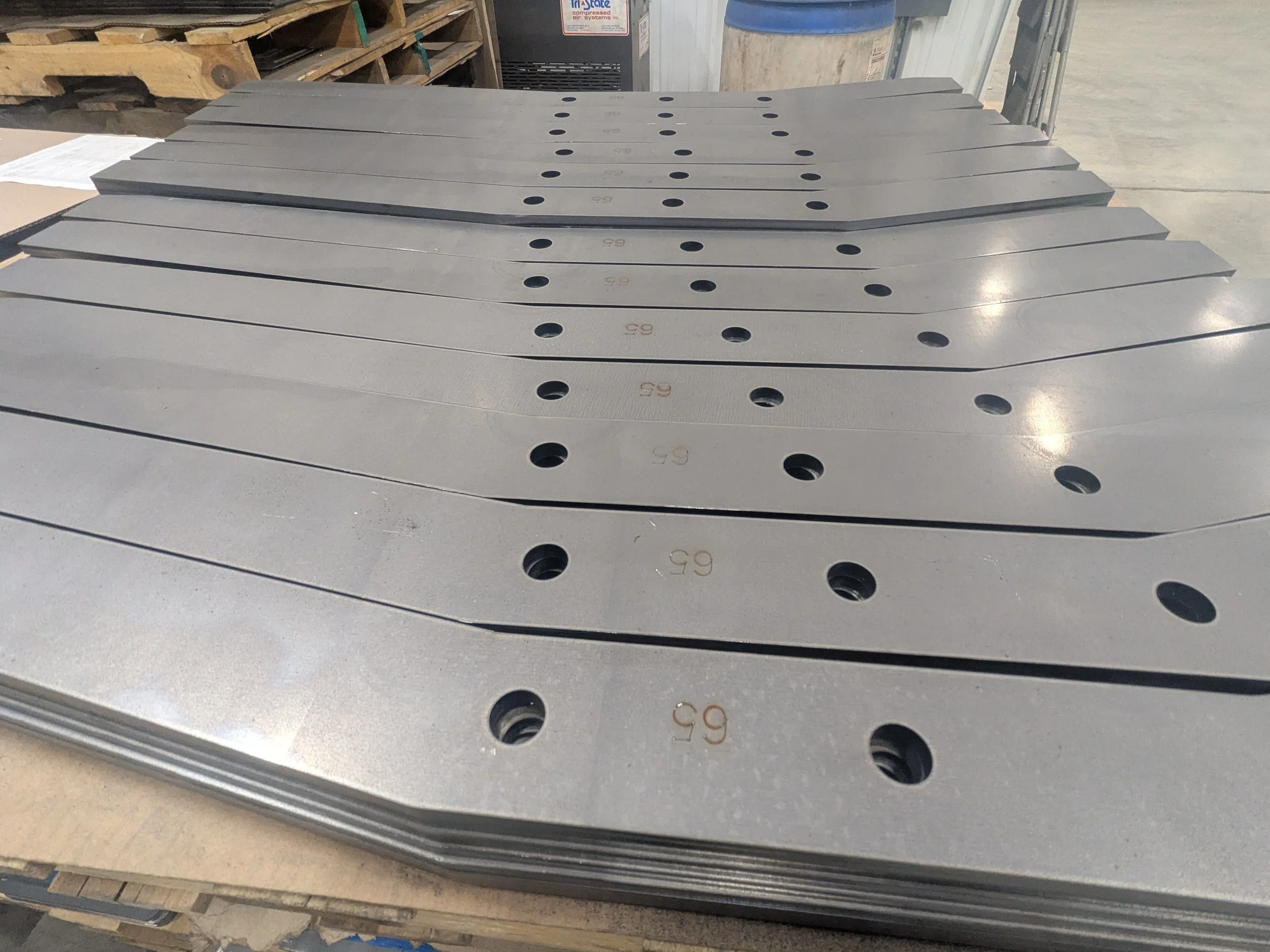

Laser etching is a precise, non-contact marking process used to permanently apply text, logos, serial numbers, barcodes, and graphics to metal surfaces without affecting part geometry or structural integrity. It is commonly used for identification, branding, and traceability across a wide range of fabricated components.

How It Works

The laser etching process begins with digital artwork or part data derived from CAD files. A focused laser beam rapidly heats the surface of the material, creating high-contrast marks by altering the surface texture or color. Unlike engraving or cutting, laser etching does not remove significant material or penetrate deeply into the metal. The process is carefully controlled to achieve consistent mark depth, clarity, and contrast while preserving the underlying material properties.

Quality & Accuracy

Laser etching delivers sharp, legible markings with exceptional detail and repeatability. Because the process is digitally controlled and non-contact, there is no tool wear and minimal risk of part distortion. Mark placement remains accurate and consistent across production runs, ensuring uniform appearance and compliance with identification or regulatory requirements.

Benefits

Laser etching provides permanent, wear-resistant markings that will not fade, peel, or wash away. It eliminates the need for inks, labels, or chemicals and supports clean, efficient production. The process is suitable for steel, stainless steel, aluminum, and other metals and accommodates both simple markings and complex graphics. Laser etching supports traceability, quality control, and professional product presentation while integrating seamlessly into fabrication workflows.