CAD DESIGN

CAD Design

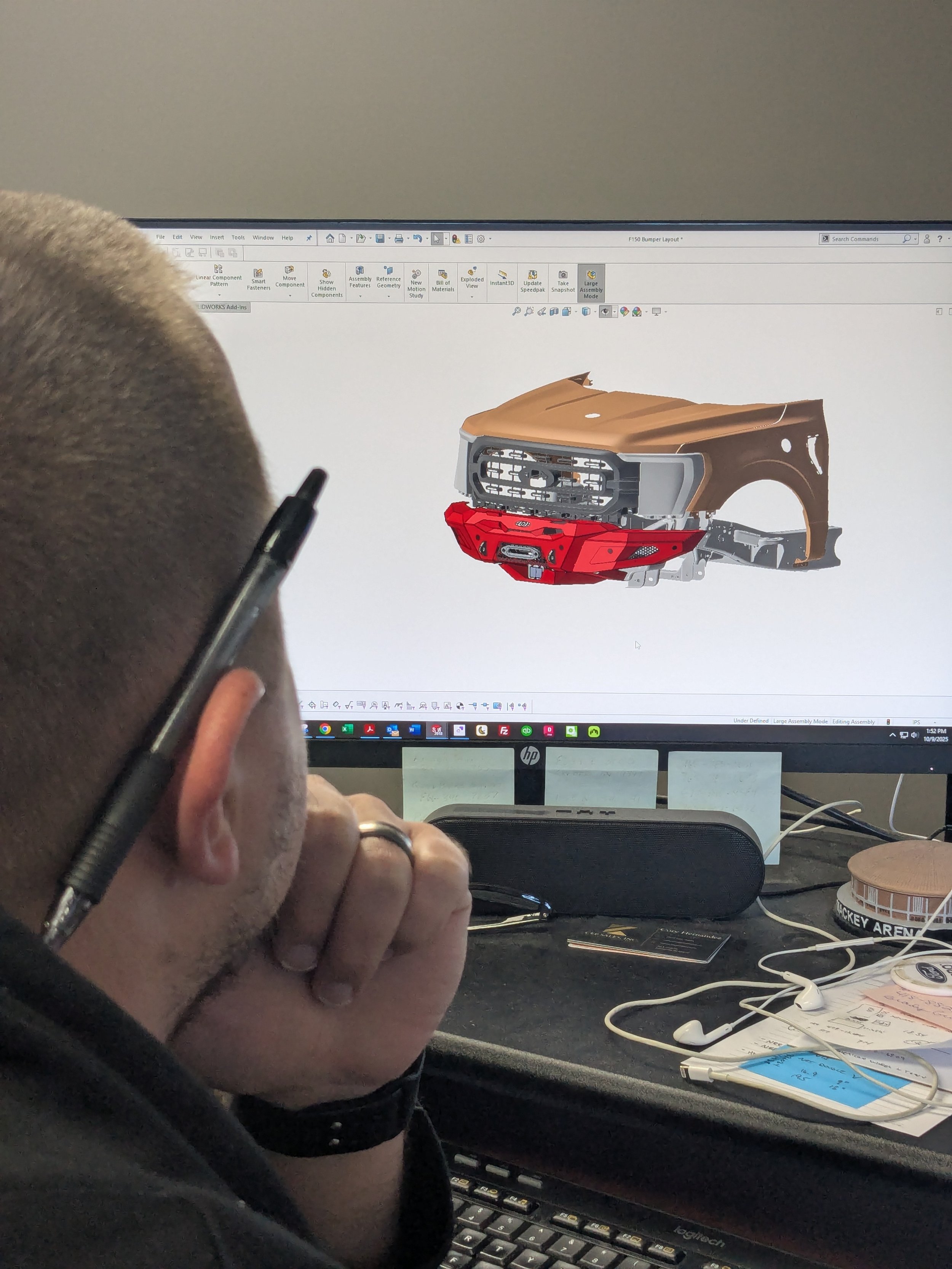

CAD design is the foundation of the metal fabrication process, where concepts and requirements are translated into detailed digital models and drawings that define part geometry, dimensions, and fabrication intent. This process ensures components are designed for accuracy, functionality, and efficient manufacturing.

How It Works

The CAD design process begins with customer specifications, drawings, or concepts. Using specialized design software, parts and assemblies are modeled in detail, incorporating dimensions, tolerances, bend information, hole locations, and assembly features. Designs are reviewed and refined to ensure proper fit, performance, and manufacturability. Considerations such as material selection, forming limits, and assembly sequence are addressed early to minimize downstream issues. Finalized designs serve as the basis for fabrication planning and production.

Quality & Accuracy

CAD design provides precise control over geometry and tolerances, allowing potential issues to be identified before production begins. Digital models enable accurate visualization, interference checks, and dimensional verification. This level of accuracy reduces errors, rework, and material waste while ensuring consistent translation from design to fabrication.

Benefits

A well-executed CAD design process improves efficiency, reduces lead times, and enhances overall part quality. It supports seamless integration with cutting, forming, machining, and assembly operations and allows for rapid design revisions when needed. CAD design enables reliable communication between engineering and production, ensuring fabricated components meet functional, dimensional, and quality requirements. This process is essential for delivering consistent, high-quality metal products.