Forming

Forming

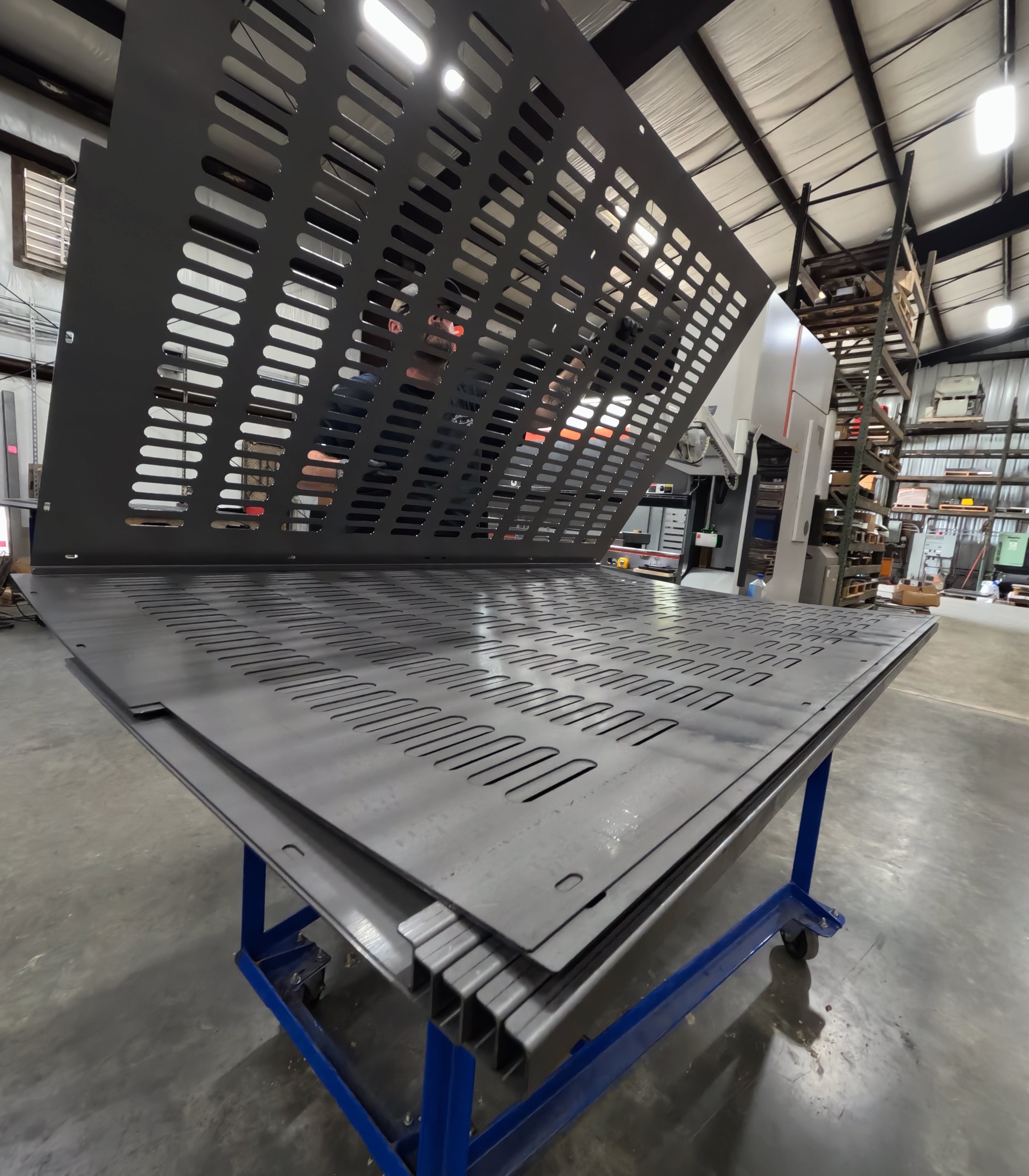

Forming is a core metal fabrication process used to reshape sheet metal into precise bends, angles, and contours without removing material. This process is essential for creating functional, structural, and aesthetic features that define the final geometry of fabricated components.

How It Works

The forming process begins with flat sheet metal that is positioned in forming equipment such as press brakes equipped with precision tooling. Controlled force is applied along predetermined bend lines to shape the material to the required angles and profiles. Proper tooling selection, bend sequencing, and setup ensure accurate results while accounting for material properties such as thickness, grain direction, and spring back. This controlled approach allows complex geometries and multiple bends to be produced consistently across a wide range of part designs.

Quality & Accuracy

Forming delivers consistent bend angles, uniform dimensions, and reliable repeatability throughout production runs. Attention to tooling condition, process control, and inspection helps maintain tight tolerances and proper part geometry. By reshaping the material rather than removing it, forming preserves material strength and structural integrity while achieving precise dimensional results.

Benefits

Forming offers flexibility and efficiency in producing complex parts while minimizing material waste. It supports both prototype development and full-scale production and is suitable for steel, stainless steel, aluminum, and other alloys. By enabling precise shaping and efficient production, forming plays a critical role in delivering high-quality components that meet functional, dimensional, and appearance requirements.