Laser Cutting Capabilities

Laser Cutting

Laser cutting uses a high-powered, focused beam to melt and vaporize metal with extreme precision, delivering clean edges, tight tolerances, and rapid production for complex geometries.

Punching

Metal punching is a fabrication process where a press drives shaped tools through sheet metal to cut holes or forms quickly and accurately, producing consistent parts for further assembly or finishing.

Plasma Cutting

Plasma cutting uses a handheld torch to generate a high-temperature, electrically charged gas that melts metal and blows it away. Skilled operators manually guide the torch to cut steel and other conductive metals quickly with accurate, clean edges.

Laser Etching

Laser etching uses a focused laser to permanently mark metal surfaces with text, logos, or patterns by altering the surface layer without cutting, ensuring high precision, durability, and repeatable results.

Saw Cutting

Precision saw cutting uses automated band and circular saws to cut metal stock to length with tight tolerances, clean edges, and minimal waste, supporting downstream fabrication and assembly.

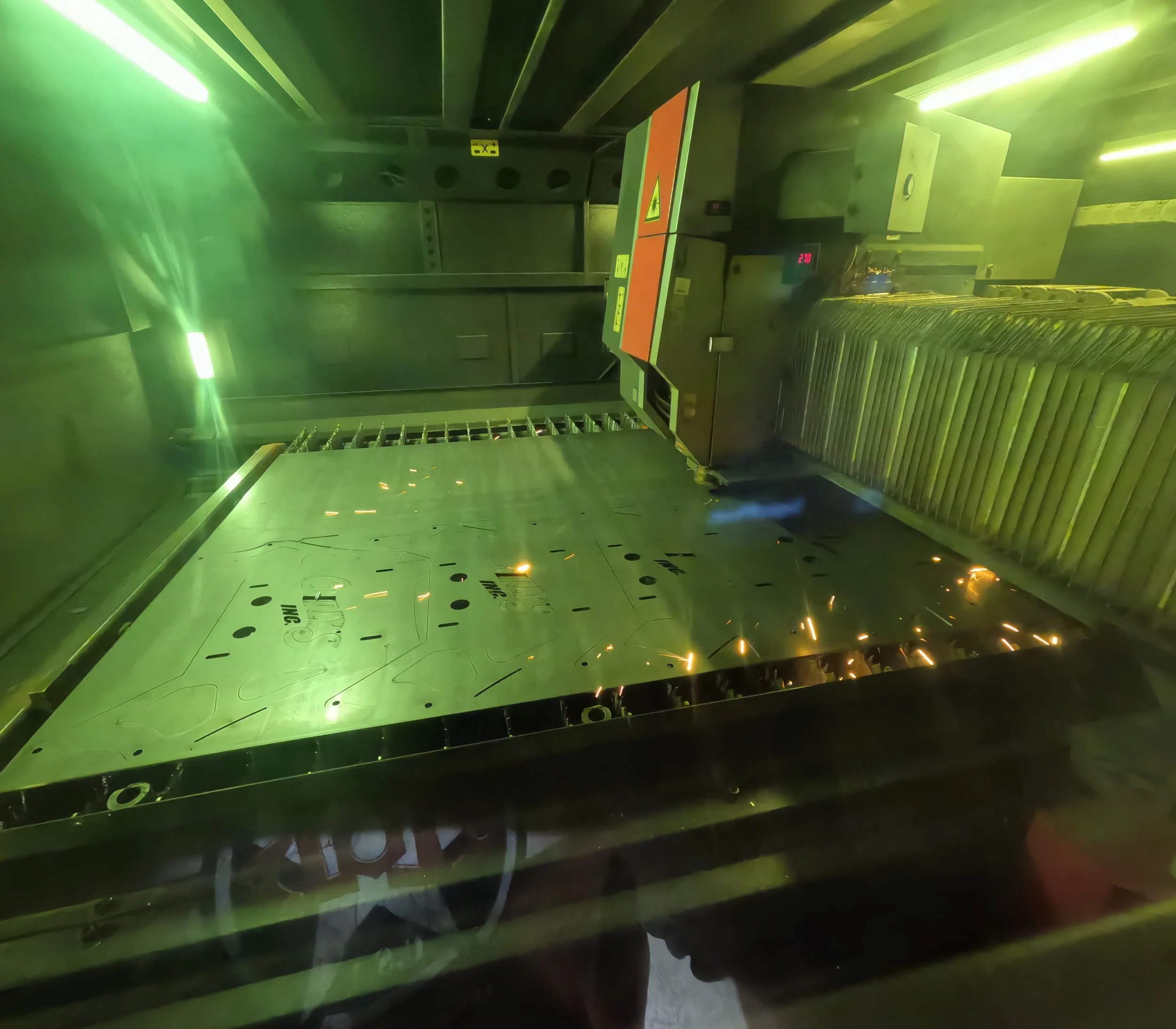

PRECISION LASER CUTTING

Precision Laser Cutting

Precision laser cutting is a computer-controlled metal cutting process that uses a focused, high-energy laser beam to produce clean, accurate cuts in sheet and plate material.

How It Works

Guided by CAD/CAM software, the laser follows programmed paths to cut complex shapes, tight tolerances, and fine details with exceptional repeatability.

Quality & Accuracy

The laser’s intense heat melts or vaporizes the material, while an assist gas removes molten metal to create smooth, high-quality edge finishes.

Benefits

As a non-contact process, laser cutting minimizes material distortion and tool wear. It is ideal for efficient, high-quality production of parts in steel, stainless steel, aluminum, and other alloys.

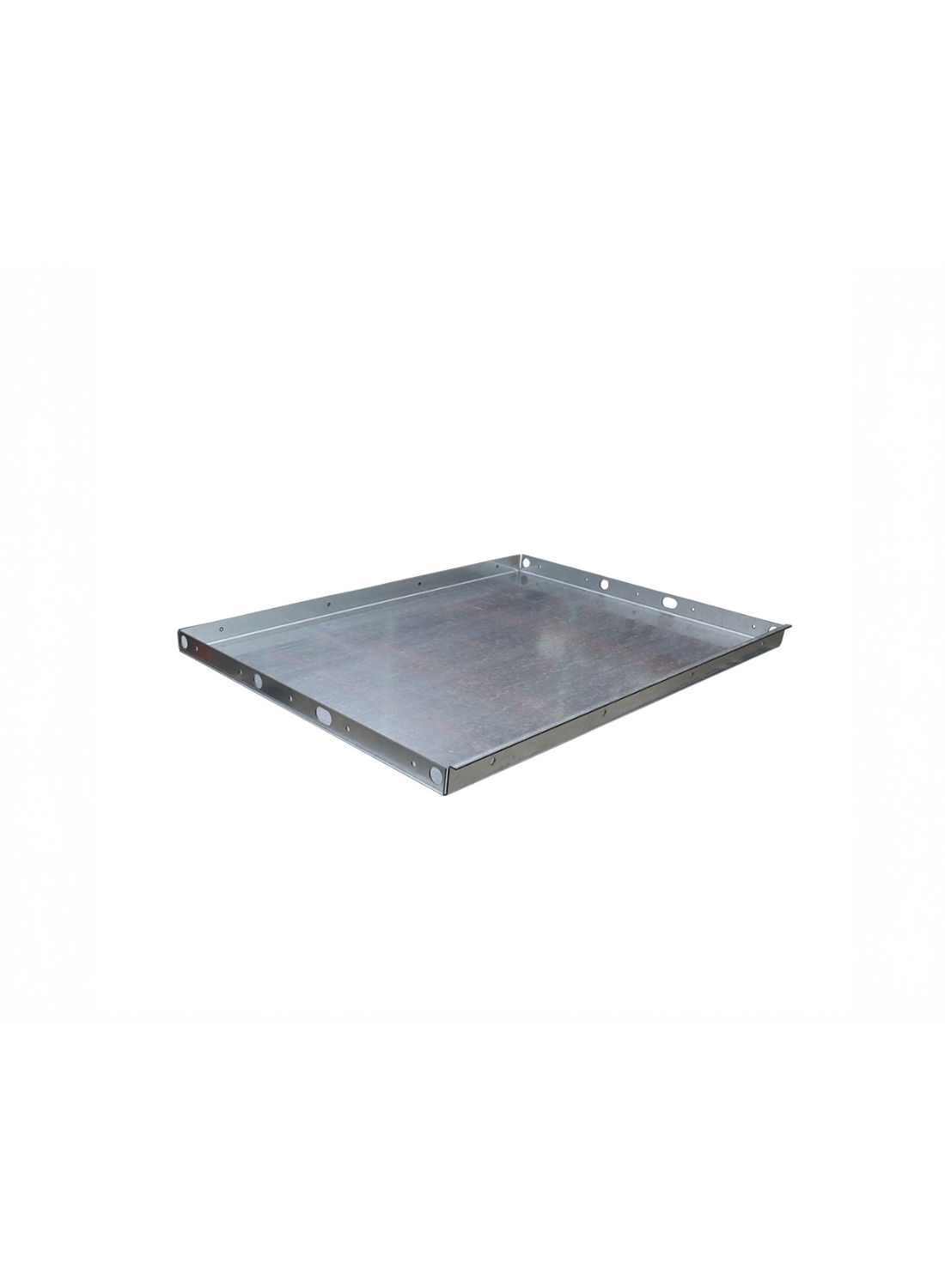

PUNCHING

Punching

Precision punching is a high-speed metal fabrication process that uses controlled force to create holes, shapes, and formed features in sheet metal with accuracy and consistency.

How It Works

Guided by CAD/CAM programming, a punch press drives specialized tooling through the material to produce precise cutouts, patterns, and features in a single or progressive operation.

Quality & Accuracy

The process delivers clean, uniform results with tight tolerances and excellent repeatability, making it ideal for both simple and complex part designs.

Benefits

Punching is highly efficient for medium- to high-volume production and allows for forming, embossing, and countersinking in one operation. It is commonly used for steel, stainless steel, aluminum, and other sheet metal materials.

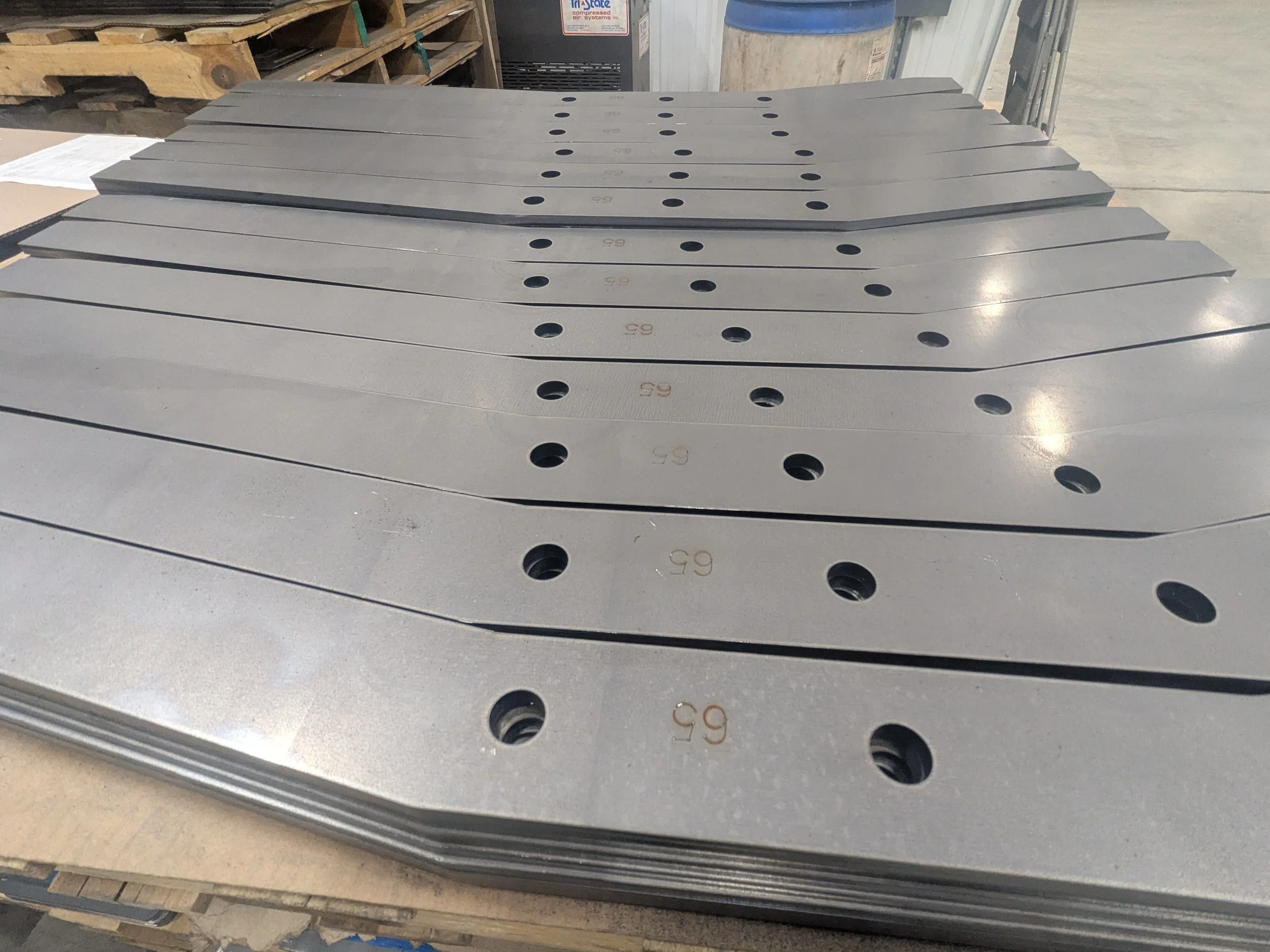

Saw Cutting

Saw cutting is a precise metal cutting process used to cut raw material to length with accuracy and consistency. It is commonly used to prepare bar stock, tubing, pipe, and structural shapes for further fabrication.

How It Works

Material is securely clamped while a precision-controlled saw blade cuts through the metal at controlled speeds, producing straight, accurate cuts across a wide range of material sizes and profiles.

Quality & Accuracy

Saw cutting produces clean, square edges with tight length tolerances and minimal material waste, ensuring parts are ready for downstream fabrication processes.

Benefits

This process is efficient and cost-effective for cutting steel, stainless steel, aluminum, and other alloys. Saw cutting supports consistent material preparation, improved production flow, and reliable part quality.

SAW CUTTING

LASER ETCHING

Laser Etching

Laser etching is a precise marking process that uses a focused laser beam to permanently mark text, logos, serial numbers, and graphics onto metal surfaces without compromising material integrity.

How It Works

Guided by CAD or digital artwork files, the laser rapidly heats the surface of the material to create high-contrast marks by altering the surface texture or color, without cutting into the metal.

Quality & Accuracy

Laser etching produces crisp, legible markings with excellent detail and repeatability. The non-contact process ensures consistent results while maintaining tight tolerances.

Benefits

This process creates permanent, wear-resistant markings ideal for part identification, branding, and traceability. Laser etching works on steel, stainless steel, aluminum, and other metals, and eliminates the need for inks, chemicals, or secondary labeling.