Other Capabilities

CAD Design

Laser cutting uses a high-powered, focused beam to melt and vaporize metal with extreme precision, delivering clean edges, tight tolerances, and rapid production for complex geometries.

Quality Inspection

Metal punching is a fabrication process where a press drives shaped tools through sheet metal to cut holes or forms quickly and accurately, producing consistent parts for further assembly or finishing.

Shipping

Laser etching uses a focused laser to permanently mark metal surfaces with text, logos, or patterns by altering the surface layer without cutting, ensuring high precision, durability, and repeatable results.

Packaging

Precision saw cutting uses automated band and circular saws to cut metal stock to length with tight tolerances, clean edges, and minimal waste, supporting downstream fabrication and assembly.

CAD DESIGN

CAD Design

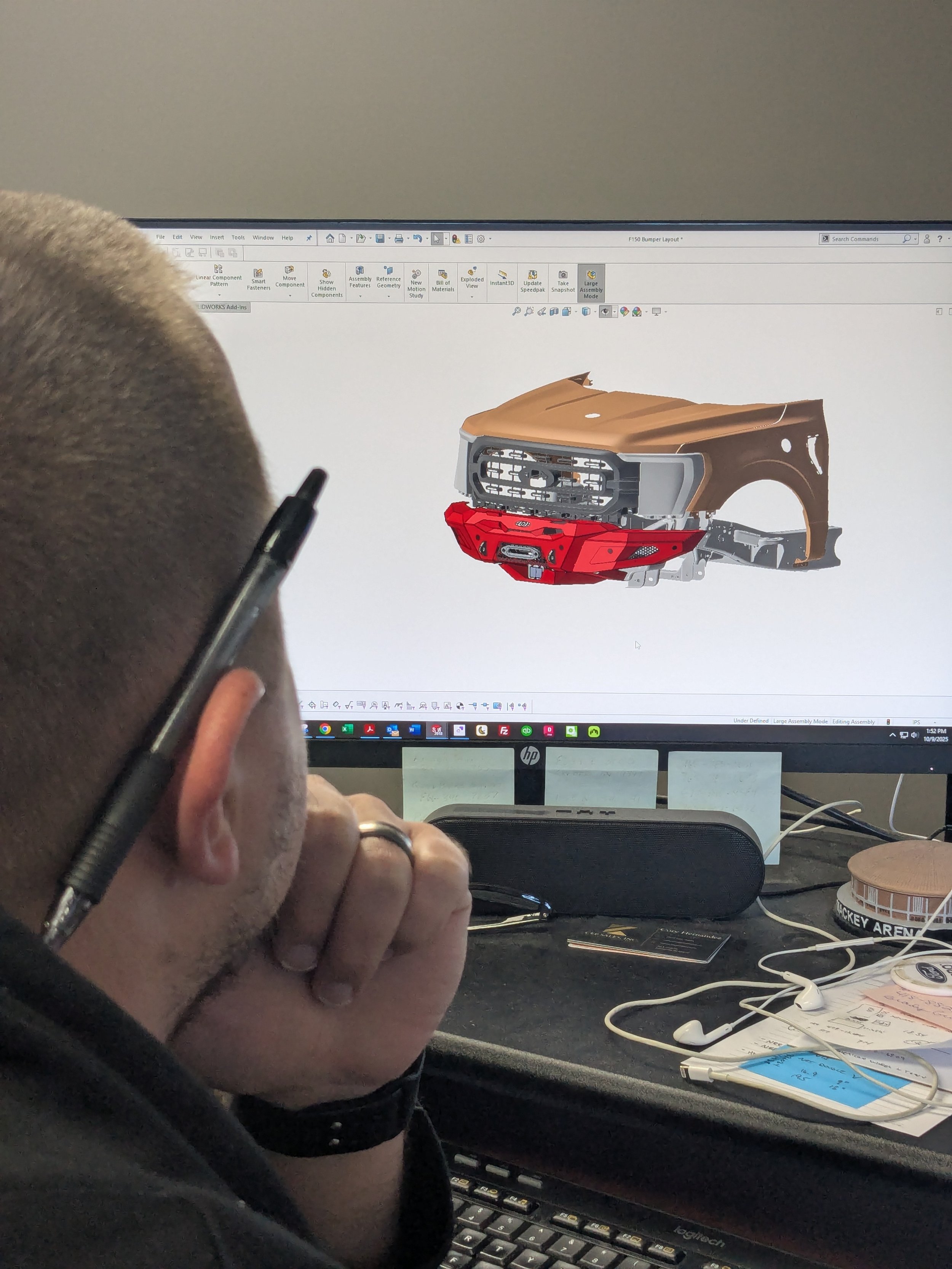

CAD design is the process of creating detailed digital models and drawings that define part geometry, dimensions, and fabrication requirements before production begins.

How It Works

Using specialized design software, parts and assemblies are developed from customer specifications or concepts. Designs are refined to ensure proper fit, function, and manufacturability.

Quality & Accuracy

CAD design provides precise control over dimensions and tolerances, allowing for accurate visualization and consistent translation to fabrication processes.

Benefits

This process reduces errors, improves efficiency, and ensures parts are optimized for fabrication. CAD design supports seamless integration with cutting, forming, and assembly operations, resulting in reliable, high-quality finished components.

QUALITY INSPECTION

Quality Inspection

Quality inspection is a critical process used to verify that fabricated parts meet specified requirements for dimensions, performance, and overall workmanship.

How It Works

Parts are inspected at key stages of production using calibrated measuring tools and visual checks. Inspections confirm dimensions, tolerances, and surface quality throughout the fabrication process.

Quality & Accuracy

This process ensures consistent compliance with specifications and helps identify issues early, maintaining high standards of accuracy and reliability.

Benefits

Quality inspection reduces defects, improves consistency, and ensures customer requirements are met. It supports reliable production, traceability, and confidence in the final fabricated components.

PACKAGING

Packaging

Packaging is the final stage of the metal fabrication process, focused on protecting finished parts during handling, storage, and transportation.

How It Works

After inspection, parts are organized, labeled, and packaged using protective materials such as wraps, separators, pallets, or custom containers to prevent movement, scratching, or damage.

Quality & Accuracy

Proper packaging preserves part dimensions, surface finishes, and order accuracy, ensuring components arrive in ready-to-use condition.

Benefits

This process minimizes damage risk, improves shipping efficiency, and supports on-time delivery. Effective packaging ensures fabricated parts maintain their quality from the facility to the customer.

Shipping

Shipping is the final logistics process that ensures completed fabricated parts are delivered safely, accurately, and on schedule to the customer.

How It Works

After packaging, orders are prepared for shipment by verifying quantities, documentation, and delivery requirements. Parts are loaded and transported using appropriate carriers to meet delivery timelines.

Quality & Accuracy

Shipping procedures focus on order accuracy, proper handling, and secure transport to maintain part quality throughout transit.

Benefits

This process supports reliable delivery, reduces delays, and provides customers with confidence that their fabricated components will arrive complete and ready for use. Effective shipping ensures a smooth transition from production to delivery.